Wolverine Fuels is uniquely structured to provide a reliable supply of high BTU low sulfur coal to a large network of domestic utility and industrial users, in addition to substantial exports to East Asian markets.

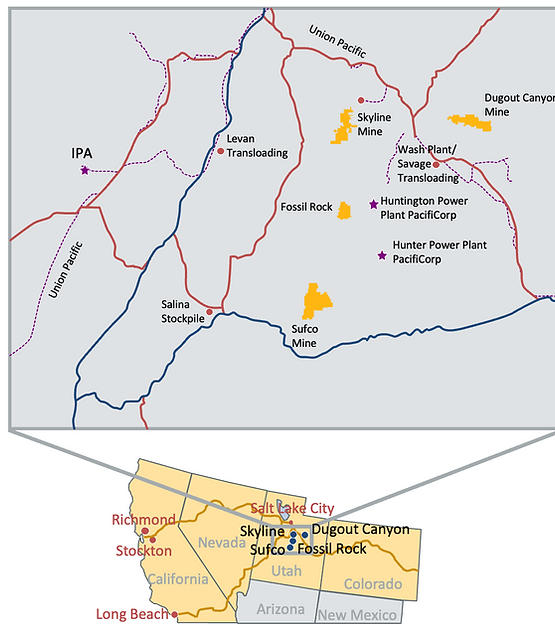

Skyline

Sufco

Fossil Rock

Transportation and Storage

We partner with Utah’s largest logistics providers to ensure reliable, safe and cost effective transportation of our coal.

Storage, Blending & Coal Beneficiation

The coal blending process combines coal of different quality, origin, or characteristic to achieve a desired composition or quality for a specific application. This process is common in industries such as power generation, steel manufacturing, and other applications requiring specific coal properties.

Key steps in the coal blending process include:

-

Unloading: Coal is delivered from multiple sources (e.g., mines) and unloaded into a blending facility.

-

Storage: Coal is stored in silos, bins, or stockpiles.

-

Conveying: Coal is transported using conveyor belts or other mechanisms to blending points.

-

Blending: Coal from different sources is mixed to meet required specifications (e.g., calorific value, ash content, sulfur content, and moisture levels).

-

Output: The blended coal is transported to end users or storage.

Wolverine stores and blends coal at Savage Energy Terminal, SR10, Castle Valley Prep Plant, and Hunter Prep Plant.